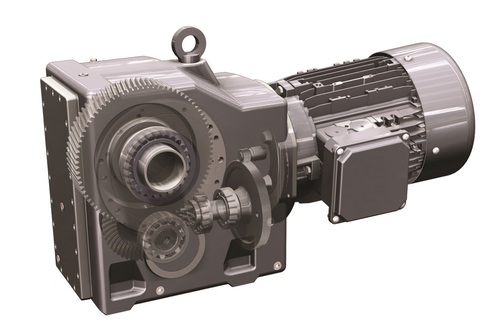

Helical Gear Motor

Price 1200 INR/ Piece

MOQ : 1 Piece

Helical Gear Motor Specification

- Gear Type

- Helical

- Material

- Cast Iron / Steel

- Processing Type

- Precision Machined

- Gear Tooth Profile

- Helical

- Gearing Arrangement

- Parallel Shaft

- Direction

- Bi-directional

- Output Torque

- Up to 3500 Nm

- Rated Power

- 0.18 kW to 160 kW

- Input Speed

- Up to 2800 rpm

- Output Speed

- 10 rpm to 500 rpm

- Voltage

- 220V / 380V / 415V

- Efficiency

- Up to 96%

Helical Gear Motor Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Domestic Market

- All India

About Helical Gear Motor

We are a trusted manufacturer, and service provider of helical gear motor and all types of gear boxes engaged in offering assured quality Gear Coupling, Industrial Gears, Gear Boxes, Chain Sprockets, Industrial Pulleys and Transmission Products.

Versatile Mounting and Robust Design

This Helical Gear Motor is available in both foot and flange mounting configurations, making installation flexible for various industrial setups. Its housing, treated with anti-corrosive paint and built from precision-machined cast iron or steel, ensures resilience in challenging operational environments and long-lasting durability for continuous applications.

Efficient Cooling and Lubrication System

Surface cooling and oil bath lubrication efficiently reduce operational heat and wear, prolonging motor life even in demanding industrial processes. The system helps maintain performance stability within a wide ambient temperature range and enhances dependability for harsh usage conditions.

Superior Performance and Low Noise

Engineered to deliver up to 3500 Nm in output torque and handle power ratings from 0.18 kW to 160 kW, this motor excels in various applications. Its helical gear design and parallel shaft arrangement provide up to 96% efficiency with minimal noise, ensuring smooth operation for conveyors, mixers, and industrial drives.

FAQ's of Helical Gear Motor:

Q: How is the Helical Gear Motor typically installed in industrial applications?

A: The Helical Gear Motor supports both foot and flange mounting types, providing users with installation flexibility for integration into a wide range of machinery such as conveyors, mixers, and conveying systems.Q: What protection classes are available for the Helical Gear Motor and what do they ensure?

A: This motor is available with IP55 and IP65 protection classes, which safeguard it against dust ingress and water exposure, thereby enhancing reliability and operational safety in challenging industrial environments.Q: When is oil bath lubrication beneficial for gear motors?

A: Oil bath lubrication is ideal for continuous-duty gear motors, as it maintains proper lubrication between moving parts, reduces wear, lowers maintenance needs, and optimizes long-term performance.Q: Where can the Helical Gear Motor be used with respect to environment temperature?

A: The motor is designed to operate reliably in ambient temperatures ranging from -10C to +50C, making it versatile for use in various indoor and outdoor industrial settings across India.Q: What is the process for maintaining low noise operation in this gear motor?

A: Low noise operation is ensured through precision machined helical gears, balanced alloy steel shafts, and robust housing design, coupled with efficient lubrication and surface cooling methods.Q: How does the anti-corrosive paint benefit the motor's housing in operational environments?

A: Anti-corrosive paint protects the cast iron or steel housing from rust, chemical exposure, and abrasive conditions, thus extending the motor's lifespan especially in demanding industrial atmospheres.Q: What are the typical industrial applications for the Helical Gear Motor in India?

A: This gear motor is widely used in conveyors, mixers, conveying systems, and other industrial drives, owing to its high torque output, continuous duty rating, and robust construction.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Repairing And Servicing Category

Helical Gear Box Servicing

Price 1200 INR / Piece

Minimum Order Quantity : 1 Piece

Gear Tooth Profile : Other, Helical

Gearing Arrangement : Other, Parallel

Processing Type : Hobbing

Gear Type : Other, Helical

WORM GEAR BOX REPAIRING AND SERVICE

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Gear Tooth Profile : Other

Gearing Arrangement : Worm

Processing Type : Precision Casting

Gear Type : Worm Gears

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS