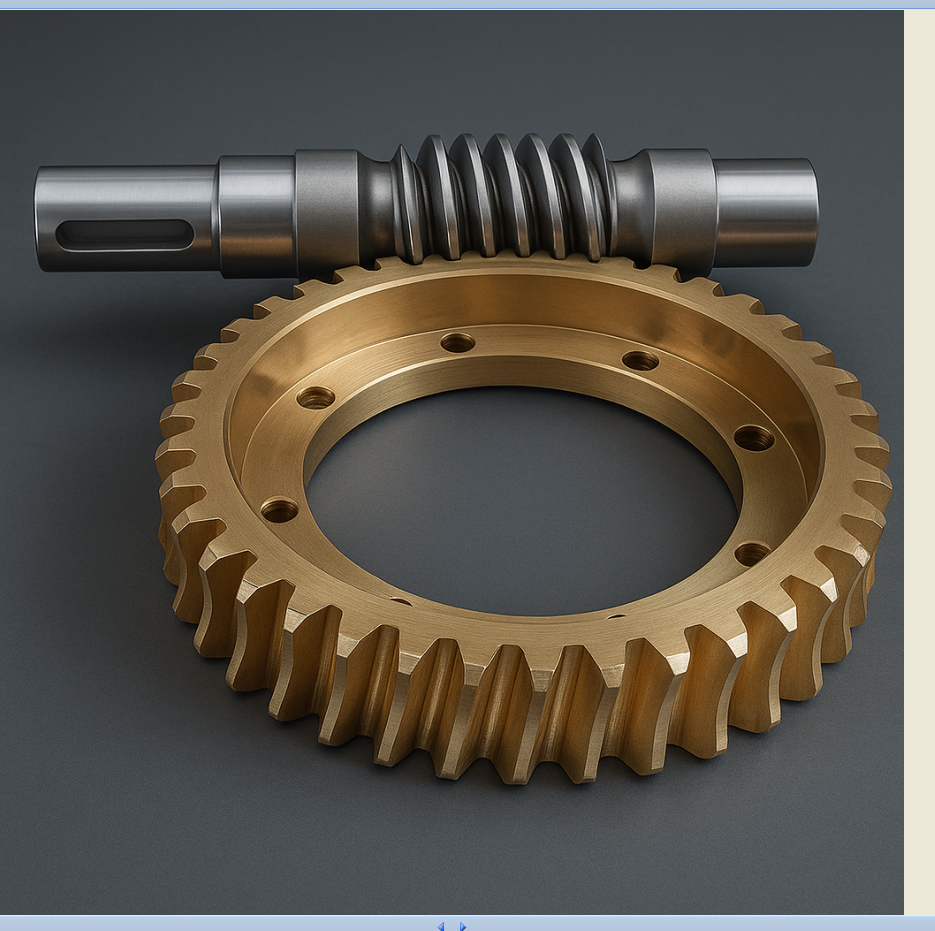

Gun Metal Worm Wheel

Price 1000.0 INR/ Piece

Gun Metal Worm Wheel Specification

- Usage

- INDUSTRIAL

- Material

- Iron

- Processing Type

- Hobbing

- Gear Tooth Profile

- Helical Gear

- Product Type

- Gun Metal Worm Wheel

- Gearing Arrangement

- Worm

- Efficiency

- Transmission Drive

Gun Metal Worm Wheel Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Paypal, Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Packing as per Customer requirement

- Main Domestic Market

- All India

- Certifications

- No Certification

About Gun Metal Worm Wheel

We have maintained goodwill in the market by offering the best quality range of Gun Metal Worm Wheel to our clients in different technical specifications. The offered wheel is manufactured at our premises using excellent quality components and ultra-modern techniques. This wheel is widely used for installation in lifts, elevators as well as hoists for transferring power from one shaft to another. In addition, the provided Gun Metal Worm Wheel can be purchased at reasonable prices from us.

Key points:

- Sturdiness

- Long life

- Supreme finish

- Accurate dimensions

Key Features:

-

- Material Composition: Constructed from gunmetal, a durable alloy consisting mainly of copper and tin, known for its excellent wear and corrosion resistance. This material ensures longevity and reliable performance under heavy use.

- Precision Machining: Engineered with high precision to ensure accurate meshing with the corresponding worm gear, reducing backlash and improving torque transmission efficiency.

- Wear Resistance: The gunmetal composition provides superior resistance to wear and tear, extending the service life of the worm wheel even under high-load conditions.

- Corrosion Resistance: The alloys inherent resistance to corrosion makes it suitable for use in environments exposed to moisture or corrosive substances, maintaining performance and appearance over time.

Precision Hobbing for Superior Performance

Our worm wheels are meticulously crafted using the hobbing process, which ensures accurate gear tooth profiles and optimal alignment. This method results in smoother operation, greater durability, and enhanced efficiency, especially suited for heavy-duty industrial environments.

Efficient Transmission Drive Solutions

Designed with a helical gear tooth profile, our gun metal worm wheels minimize power loss and deliver efficient torque transfer. Their robust construction and reliable gearing arrangement enhance the performance of industrial machinery, reducing maintenance needs and operational downtime.

FAQs of Gun Metal Worm Wheel:

Q: How is the Gun Metal Worm Wheel manufactured?

A: The wheel is produced using a hobbing process, which involves precision machining of high-quality iron. This ensures accurate worm and helical gear profiles, resulting in smooth and reliable power transmission.Q: What are the typical applications of this worm wheel in industry?

A: It is commonly used in mechanical transmission drives within various industrial machines. Its design is especially suitable for cases requiring high torque and efficient motion transfer, such as conveyors, elevators, and heavy-duty processing equipment.Q: When should I consider using a worm wheel with a helical gear tooth profile?

A: Such a gear is ideal when your application demands quiet operation, maximum contact ratio, and minimal vibration. The helical profile enhances load distribution, making it perfect for continuous industrial usage.Q: Where are these worm wheels manufactured and traded?

A: Our gun metal worm wheels are both manufactured and distributed in India, adhering to stringent quality standards to ensure consistent reliability for clients across various industrial sectors.Q: What is the benefit of the worm gearing arrangement used in this product?

A: A worm gearing arrangement offers significant speed reduction and high torque output with minimal space requirements. It also helps prevent back-driving, enhancing operational safety in industrial systems.Q: How can using a Gun Metal Worm Wheel improve transmission drive efficiency?

A: Its helical gear tooth profile reduces friction and power loss within transmission systems, resulting in smoother motion and improved overall efficiency, thus prolonging machinery lifespan and reducing energy consumption.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Worm & Worm wheel Category

Industrial Worm Wheel

Price 1000 INR / Piece

Minimum Order Quantity : 15 Pieces

Processing Type : Hobbing

Gearing Arrangement : Worm

Gear Tooth Profile : Helical Gear

Material : Iron

Precision Worm Wheel Gear

Price 1000 INR / Piece

Minimum Order Quantity : 20 Pieces

Processing Type : Hobbing

Gearing Arrangement : Worm

Gear Tooth Profile : Helical Gear

Material : Iron

Worm Gear Box

Price 5000 INR / Piece

Processing Type : Other, Machined

Gearing Arrangement : Worm

Gear Tooth Profile : Other, Helical

Material : Other, Cast Iron

Bronze Worm Wheel

Price 1000.00 INR / Piece

Minimum Order Quantity : 15 Pieces

Processing Type : Precision Casting

Gearing Arrangement : Worm

Gear Tooth Profile : Helical Gear

Material : Other, Bronze

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS