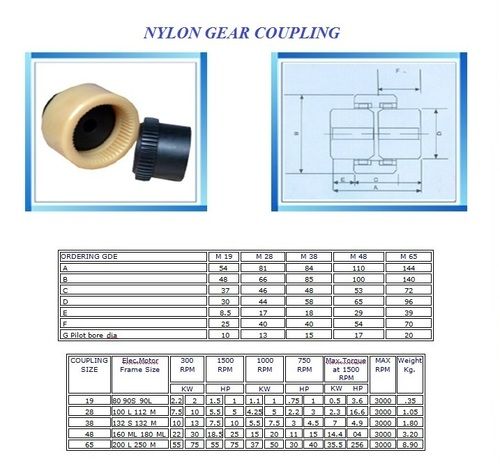

Nylon Gear Coupling

Price 1000.0 INR/ Unit

MOQ : 1 Unit

Nylon Gear Coupling Specification

- Bore

- PILOT

- Head Code

- Round

- Connection

- Other

- Usage

- Industrial

- Material

- Steel

- Structure

- Gear

- Size

- AS PER REQUIREMENT

- Product Type

- Nylon Gear Coupling

- Inner Diameter

- 16 65 mm Millimeter (mm)

- Outer Diameter

- 83 132 mm Millimeter (mm)

- Weight

- 5 Kilograms (kg)

- Color

- White Black

- Width

- AS PER REQUIREMENT Millimeter (mm)

- Length

- AS PER REQUIREMENT Millimeter (mm)

- Application

- Torque Transmission

- Surface Treatment

- Polishing

- Technique

- Forged

- Shape

- Round

Nylon Gear Coupling Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- VADODARA

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

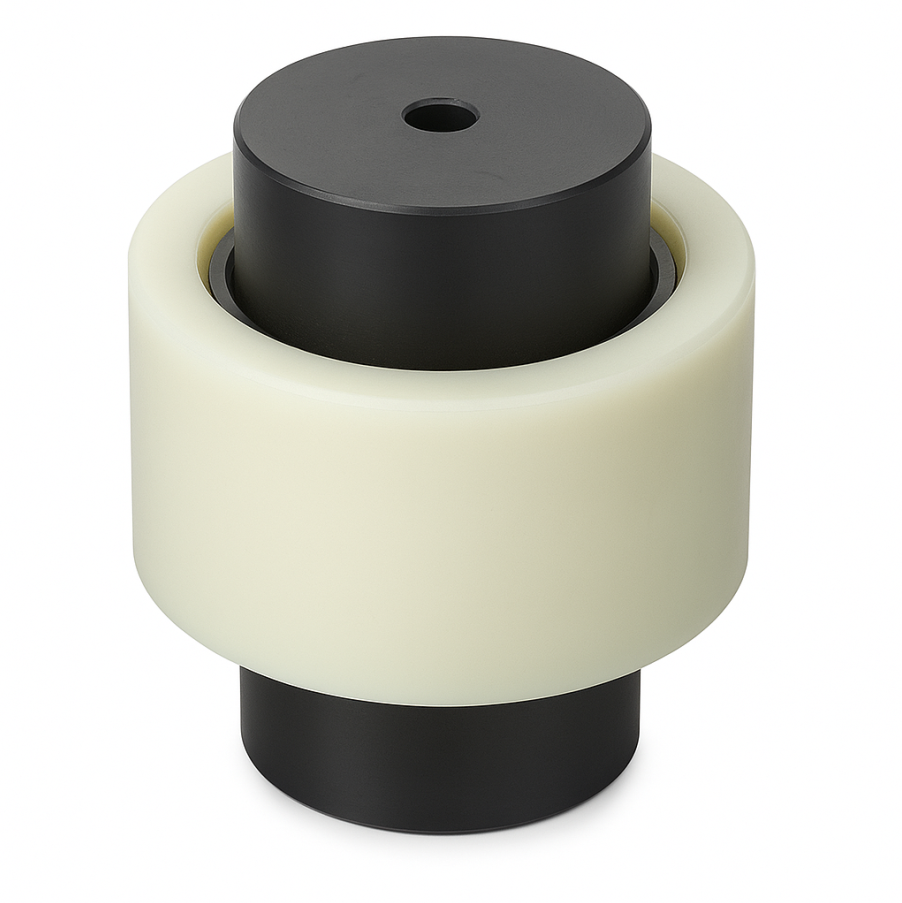

About Nylon Gear Coupling

We are offering our client an excellent quality range of Nylon Gear Coupling. These Nylon Gear Coupling are made from very high quality raw material which ensures high durability at its user end. These Nylon Gear Coupling are in high demand in the market. Different sizes and designs are easily available in the market. Our Nylon Gear Coupling are available at industrial leading prices.

COUPLING SIZE

COUPLING SIZE

- 1>19 NO.

- 2>28 NO.

- 3>38 NO.

- 4>48 NO.

- 5>65 NO.

Reliable Torque Transmission

Designed to facilitate seamless torque transfer, our Nylon Gear Couplings adapt well to varying loads in industrial scenarios. The gear sleeve structure provides flexibility and reduces vibration, enhancing equipment longevity and minimizing maintenance downtime.

Versatile Sizing and Application

With outer diameters from 83 to 132 mm and inner diameters from 16 to 65 mm, our couplings accommodate various shaft sizes. Their round shape and steel body fit perfectly in different mechanical assemblies, ensuring versatility across multiple industrial applications.

FAQs of Nylon Gear Coupling:

Q: How are Nylon Gear Couplings installed in industrial machinery?

A: Nylon Gear Couplings are typically aligned with the shafts of connected equipment, then secured using fasteners. Proper alignment ensures efficient torque transmission and reduces wear, enhancing operational stability.Q: What materials are used in the construction of these gear couplings?

A: These gear couplings are manufactured using high-grade steel, offering excellent strength and durability, while the gear sleeves are crafted from resilient nylon, providing smooth engagement and reduced noise.Q: When should I use a gear sleeve coupling for torque transmission?

A: A gear sleeve coupling is ideal when you require accurate torque transmission between shafts, especially in environments with slight misalignments or where vibration damping is crucial for machinery operation.Q: Where are these nylon gear couplings commonly employed?

A: These couplings are used in various industrial sectors across India, such as manufacturing, mining, and processing plants, wherever high performance and reliable torque transfer are essential.Q: What is the process involved in achieving the polished surface treatment?

A: The couplings undergo precision polishing during manufacturing. This process removes surface imperfections and enhances corrosion resistance, resulting in improved appearance and longer service life.Q: How does the shape and size of the coupling benefit mechanical assemblies?

A: The round design and wide range of diameters enable easy integration with assorted shaft sizes, ensuring a snug fit and optimal torque transmission, which benefits flexibility in assembly and operation.Q: What advantages do nylon gear sleeve couplings offer over conventional couplings?

A: Nylon gear sleeve couplings deliver smoother motion, lower noise, and superior resistance to wear and misalignment compared to traditional rigid couplings, resulting in longer operational lifespan and reduced maintenance costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gear Coupling Category

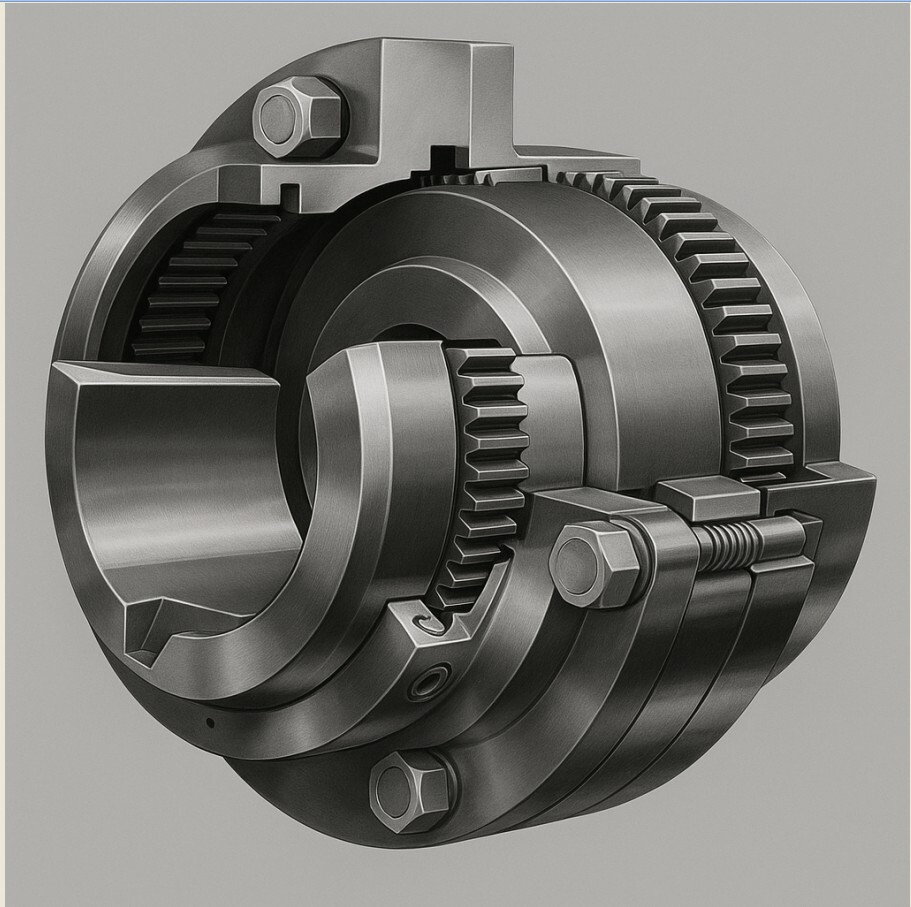

Gear Coupling

Price 1000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Shape : Round

Structure : Gear

Application : INDUSTRIAL USE

Connection : Other

HALF GEAR COUPLING

Price 1279.0 INR / Unit

Minimum Order Quantity : 1 Piece

Shape : Round

Structure : Gear

Application : INDUSTRIAL

Connection : Other

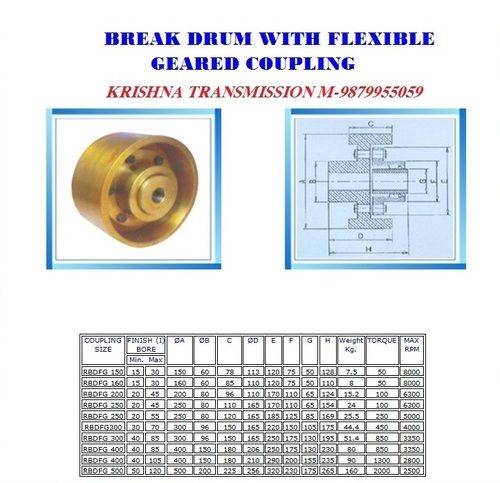

Flexible Brake Drum Gear Coupling

Price 1000 INR / Piece

Minimum Order Quantity : 20 Pieces

Shape : Round

Structure : Gear

Application : Transmission Product

Connection : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS